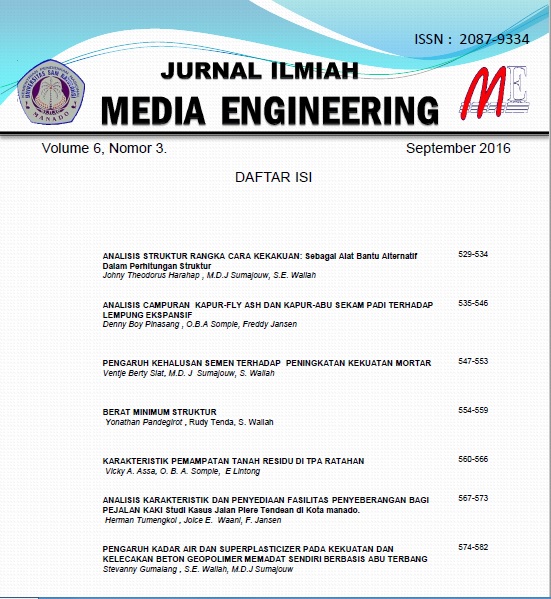

PENGARUH KADAR AIR DAN SUPERPLASTICIZER PADA KEKUATAN DAN KELECAKAN BETON GEOPOLIMER MEMADAT SENDIRI BERBASIS ABU TERBANG

Abstract

Abstract

Eenvironmental issues that caused by the production of portland cement and the development needs of the concrete casting technology, where in the last few decade scientists has started to do research and development of fly ash based - self compacting geopolymer concrete. Fly ash based - self compacting geopolymer concrete is a concrete which made of geopolymer material (fly ash) that combined with aggregate without using of portland cement. It is must have workability criteria of self compacting concrete (SCC). To get SCC’s required workability, it needs addition of extra water to the mixture of geopolymer concrete. But with the addition of extra water, the mixture of fresh geopolymer concrete could undergo dispersion and segregation, also might be affect to the chemical binding of geopolymer material. So, it needs admixture material such as superplasticizer which serves to increase workability of fresh geopolymer concrete although the amount of water content is reduced. From the description above, the author conducted a study that aims to determine the extent of the influence of water and superplasticizer on the workability and compressive strength of fly ash based -self compacting geopolymer concrete.

Fly ash based- Self Compacting Geopolymer Concrete planned as follows, Fly ash (Class F) in dry condition; coarse and fine aggregates in a SSD condition; Sodium Hydroxide’s concentration is 14M; Alkaline / Fly Ash Ratio is 0.8; Doses of Viscocrete-10 are 0%, 1%, 2% and 3%; Extra Water / Fly Ash ratio are 0, 0.2, 0:25, 0.3, and 0,32; curing in an oven for 48 hours at temperature 70 °C.

The maximum slump flow value according to EFNARC for Self Compacting Concrete is 67 cm that obtained on the addition of 3% superplasticizer and the ratio of extra water / fly ash is 0.3. Filling ability and viscosity specified in the V-Funnel test is 9.50 seconds. The test results of passing ability using the L-shaped box shows blocking ratio H2 / H1 is 0.83 seconds. Extra Water on Geopolymer Concrete provide significant impact on the slump flow value. Addition of extra water 0.3 is already getting slump flow value required by EFNARC for self compacting concrete ( 67 cm > 65 cm). The optimum composition in terms of qualified workability of Self Compacting Concrete and compressive strength are obtained on the addition of 3% superplasticizer and 0.3 extra water ratio. They give slump flow value at 67 cm and an average compressive strength of 16.28 MPa. So that in this composition, the concrete can be categorized as fly ash based - self compacting geopolymer concrete. The maximum compressive strength obtained on the mixing without extra water which is gives an average 30.55 MPa.

Keywords: water content, superplasticizer, workability, compressive strength, Self Compacting Geopolymer Concrete

Downloads

Published

Issue

Section

License

Copyright (c) 2017 Stevanny Gumalang, S E Wallah, M. D.J Sumajouw

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

- I declare that this paper ... (title of paper) ... is original and has not been published previously nor under consideration to be published elsewhere and that any necessary permission to quote from another source has been obtained.

- With the publication, I transfer the copyright to The Jurnal Ilmiah Media Engineering (PTSU-OJS). This copyright transfer shall cover the exclusive right to reproduce and distribute the article, including reprint, photographic reproduction of similar nature and translation. It shall also include the right to adapt the article for use in conjunction with computer system and programs including reproduction or publication in machine-readable form and incorporation in retrieval systems.

Author (also on behalf of any co-authors):

Signed

____________________Â

Name :

Date :